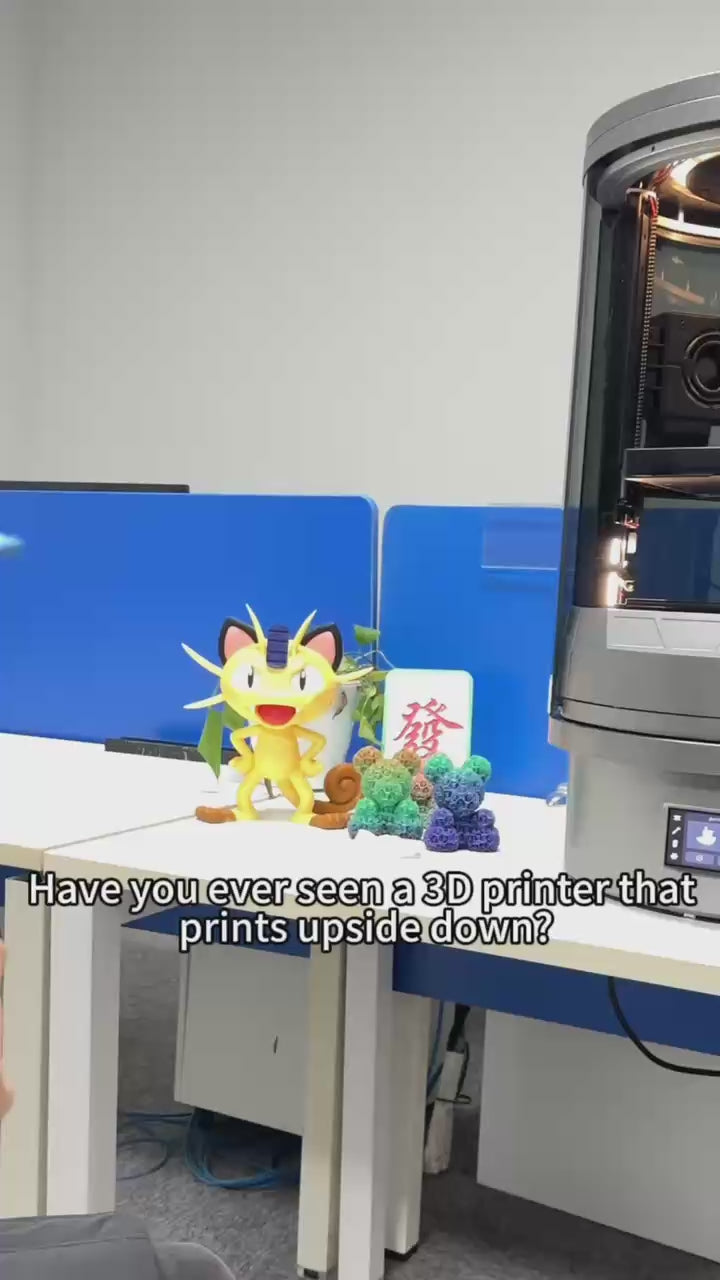

KOKONI SOTA 3D Printer (Pre-Order- Shipping in February)

SKU: KOKONI-SOTA

Vendor: KOKONI 3D Printing

Have a question?

Share

Guaranteed Safe Checkout

Shipping Schedule: The SOTA (main unit) will arrive at foreign warehouse at late Feburary. For those who purchase SOTA and SOTA combo, the delivery begins once after the SOTA have arrived at our foreign warehouse. The Flexi-Filament Tower is scheduled to arrive one month later.

|

Basic Info |

||

|

KOKONI SOTA |

||

|

Package Dimensions (WxDxH) |

580x580x760mm |

|

|

Product Dimensions (WxDxH) |

420x420x693mm |

|

|

Gross Weight |

31KG |

|

|

Net Weight |

24KG |

|

|

Printing Size (Inch) |

8.27(X)*7.87(Y)*9.06(Z) |

|

|

Printing Size (mm) |

210(X)* 200(Y) *230(Z) |

|

|

Printer |

||

|

Material |

Metal |

|

|

Casing |

Plastic Full Enclosure |

|

|

XY Axis |

High-Precision Linear Rail (Dust Proof) |

|

|

Z Axis |

High-Precision Ball Screw |

|

|

Power |

AC100-250V, 50/60Hz; 3.5A/115VAC,1.8A/220VAC |

|

|

Print Bed |

||

|

Print Surface |

Glass (Coated and Heated)*1 |

|

|

Automatic Leveling |

Auto-Bed Leveling |

|

|

Printing Speed |

||

|

Max Movement Speed |

600mm/s |

|

|

Max Acceleration |

21000mm/s^2 |

|

|

Cooling & Filtering |

||

|

Chamber Cooling Fan |

√ (with speed control) |

|

|

Filter |

Activated Carbon Filter |

|

|

Filament |

||

|

Max Filament Num. |

7 (2 + 5 with Flexi-Filament Tower) |

|

|

Filament Diameter |

1.75 mm |

|

|

Filament Supported*3 |

PLA, PETG, ABS, TPU, etc. Recommend to use KOKONI Official filament |

|

|

Intelligent Features |

||

|

Sensor |

Optical Radar |

|

|

Built-In L ED |

√ |

|

|

Built-In Camera |

1080p Timelapse and remote monitoring camera & Al Recognition |

|

|

Filament Detection |

√ |

|

|

Electronic Device |

||

|

Application Processor |

Quad-Core1.8GHz & 1.0 TOPS NPU |

|

|

OTA Update |

√ |

|

|

Communication |

WiFi / Bluetooth / USB |

|

|

Operational Interface |

KOKONI3D APP/ PC Software / 3.5" Touch Screen |

|

|

Software |

||

|

Slicer Software |

KOKONI 3D App & KOKONI 3D Plugin, Support mainstream modeling software such as Solidworks, SketchUp, CATIA, Blender. Support third party slicers which export standard G-code such as Orca slicer, Prusaslicer, Cura and Slic3r. But some functions may not be supported while using thirdparty slicers |

|

|

Input Format |

STL / OBJ / 3MF / JPG / PNG 3DS, FBX, STEP, IGES, X_T, skp, CATPart, CATProduct, SLDPRT, SLDASM, blend. ( Need to use KOKONI's plugin for third party 3D modeling software ) |

|